Share to:

Related Products

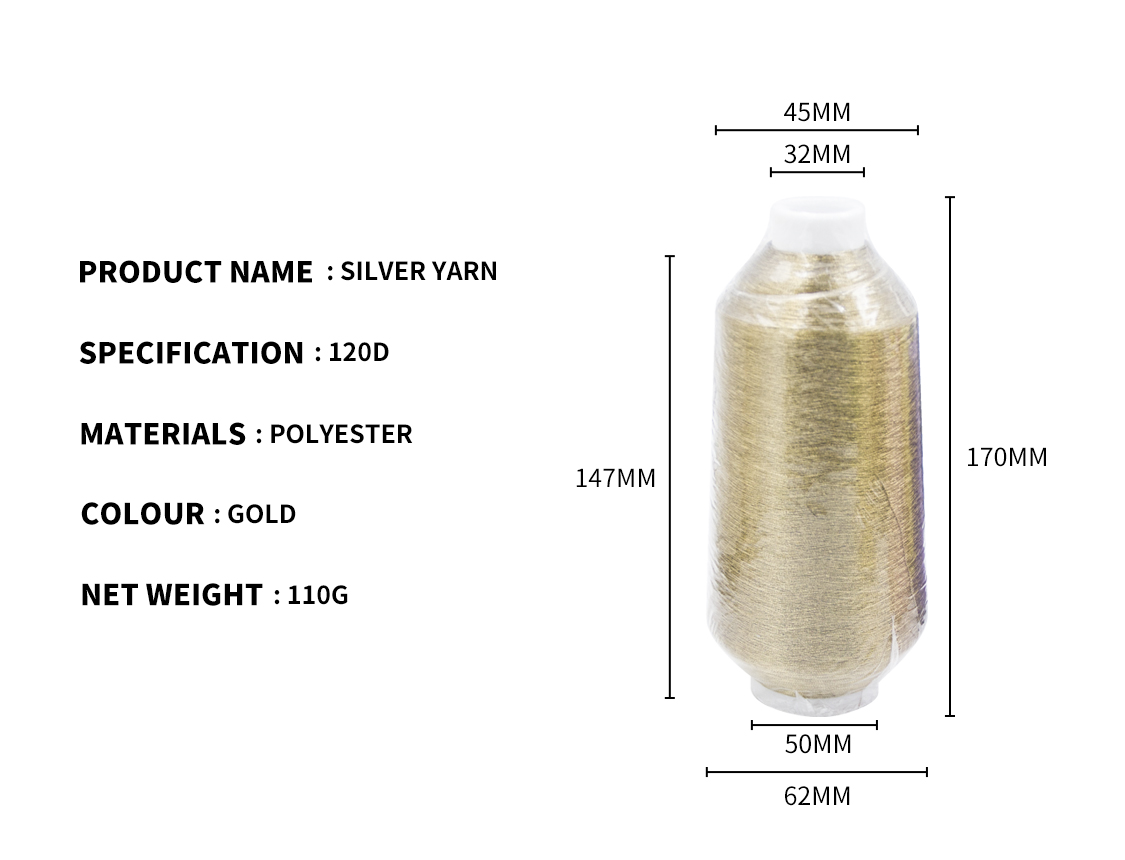

Garment decoration polyester cotton pure gold silver yarn

LQ-10-09

Price: From $2

Delivery time: 9-20 days after payment

MOQ: 500 kg

Type:Silver yarn

Material:Polyester / cotton

Yarn type:H-Type

Feature:Anti-bacteria, anti-pilling

Use:Knitting, weaving, embroidery

Yarn Count:120D, 150D, 600D

Place of origin:Guangzhou

Brand name:Customized Liqi

Model number:Silver yarn

Colors:Customized

Application:Garment decoration

Quality:100% SS fiber

Composition:One silver film twisted polyester yarn

Ratio:57% Polyester yarn twist

Sample:Provide

Paper cone:50g

Wet fastness:Level 4

Dry fastness:Level 3

Name: Gold silver yarn

Specification: 150D/1s

Yarn: None

Fineness: 0.16

Colour: Colorful

Origin: Guangzhou

Quality grade: Excellent products

Main raw materials: Gold and silver silk yarn

Type: Sewing yarn thread

Shape: Tapered or flat paper tube

Uses: Clothing, sweater, embroidery, stockings, towels, decorative cloth, etc.

Liqi Textile is a well-known domestic and foreign enterprise specializing in yarn production and sales. Since its inception for many years, the company has been adhering to the service policy of "quality, development; management, efficiency; quality, good reputation", and striving to integrate enterprises with the international standards. Our company has a group of sales enterprise full of enthusiasm and perseverance, meticulous sales service, after-sales service work, know how to operate, good management, marketing, excellent service team, the products operated in domestic and foreign counterparts and customers enjoy high reputation, with strong economic strength, good after-sales service, to provide customers with sales.

Gold silver inlaid yarn fabric woven with gold and silver yarn

What is inlaid gold and silver wiring?

Silver-inlaid textiles are made of polyester film yarn sprayed with aluminium powder in a vacuum machine and then coated with a protective layer, which is cut into silver. Gold, red, green and other colored gold and silver yarns and yellow, silver or red, green two-sided color gold and silver yarns are formed by painting in vacuum before cutting.

In addition to directly inserting gold and silver yarns into fabrics, gold and silver yarns are intertwined into flower yarns, knot yarns are woven to make fabrics shiny and wear fastness better. Some products are treated with quick swing finishing, which makes hand feel and elasticity better.

The use and maintenance of medium-length tweed inlaid with gold and silver yarn thread are basically the same as that of ordinary medium-length fibers. Do not use boiling water when washing, it is advisable to use cold water or water whose temperature does not exceed 50 degrees Celsius; do not expose to the sun, should dry in a cool place; generally do not need ironing, if ironing needs to be padded with wet cloth, ironing temperature should not be too high.

In addition, because the fabric is inlaid with gold and silver yarn, we should also pay attention to the cloth should be cut with scissors, can not be torn by hand, otherwise, because of the poor retraction of gold and silver yarn, resulting in wrinkling of gold and silver yarn on the cloth surface, affecting the beauty; the raw materials of medium and long wool are mostly polyester and viscose blended yarn, viscose fibre is not alkali-resistant, and gold and silver yarn is not acid-alkali-resistant, therefore.

When washing, it is better not to use soap which is too alkaline, but synthetic detergent which is neutral, so as to prevent the aging of fibers; when washing, do not twist and twist the fabric or rub it with a rubbing board, let alone rub it with a hard brush, which will break the gold and silver threads and damage the fastness of the fabric; you can rub it lightly by hand or use a soft brush to dry a little water. Let's straighten it out and air it.

Physical and mechanical properties of gold and silver yarns:

1. The fineness of gold and silver yarn thread is closely related to its thickness and width.

2. The strength and elongation of gold and silver yarns are low, and the elastic deformation recovery performance is poor.

This is because the yarn is cut by polyester film without stretching, the orientation and crystallinity of macromolecules are low, and the structure is loose.

Therefore, if the tension is too large or the elongation exceeds a certain limit, the yarn will easily be elongated and irreversible plastic deformation will occur, and the resin surface will easily crack, peel off and discolor.

Therefore, the fabrics embedded with gold and silver filaments should avoid large tension in the whole process of weaving and reduce the friction resistance of the channel.

Heat resistance of gold and silver yarn:

1. Dry-heat resistance is better than wet-heat resistance. If the dry heat setting temperature of the fabric can reach 180 C, the ironing temperature after washing can also reach 130 C - 140 C, but the temperature can not exceed 100 C in wet treatment. If the wet heat treatment temperature is too high or the time is too long, the outer protective layer of gold and silver wires will easily peel off and discolor, and the wires will also be heated and curled.

2. The washing temperature and time of gold and silver yarn are related to the properties and content of soap. If the soap sheet or soap content is 5 g/l, the washing temperature can be increased appropriately because of the low alkali concentration of the washing solution.

If the soap content is increased to 10 g/l, the washing temperature should be reduced appropriately because of the increase of alkali concentration. Otherwise, under the combined action of alkali and heat, the surface layer of the line and the aluminium sheet will be easily eroded and separated and peeled.

3. It is related to structure. The composite structure of gold and silver yarn is superior to the single-layer structure.

Chemical resistance of gold and silver yarn:

1. Acid and alkali resistance. According to the test, the acid and alkali resistance of gold and silver yarns made of pure aluminium and aluminium alloys are weak, because the aluminium layer is easily oxidized and discolored when it meets sodium hydroxide (caustic soda).

Although the aluminium layer of gold and silver wires is coated with resin protective layer, the edge of the film after cutting is still exposed to the outside, so the alkali solution still corrodes the aluminium foil in the post-processing.

Therefore, the fabrics embedded with gold and silver yarn should not be treated for a long time in water bath with high alkali concentration.

Similarly, the aluminium foil layer of the wire will be damaged when treated at high temperature with high concentration of sulfuric acid or hydrochloric acid bath.

Therefore, the 4-9 value of gold and silver yarn fabrics is best controlled during post-processing.

The temperature should never exceed 100 C, and the time should be controlled within 30 minutes.

1. Solvent resistance. According to experiments, gold and silver yarns are insoluble in most solvents. If 100% benzene or carbon disulfide, ether, etc. are used, the surface of gold and silver yarns will not peel off and discolor if treated at room temperature of 21 C for less than 30 minutes, but the resistance of gold and silver yarns to acetone is poor. If treated in room with 100 acetone for half an hour, the gloss of the yarns will disappear completely.

2. Light resistance. According to the test, the light fastness of gold and silver yarns is better. For example, the carbon arc test of Japanese Manmelon gold and silver yarns shows that the light fastness of domestic gold and silver yarns is over 20 hours.

The color fastness of domestic gold and silver yarns can also reach 5 grades. This shows that gold and silver yarns can withstand long exposure to sunlight without discoloration, mainly because of their watches. Smooth and bright layer, higher reflectivity of light, less absorption.

Dyeing and finishing of gold and silver yarn fabrics:

1. When using gold and silver yarns in silk fabrics, great attention should be paid to the concentration, time and temperature of refining alkali liquor. Generally, when the temperature exceeds 98 C, the PH value should be controlled below 9 and the time should be 30 minutes; if the fabric is placed too long, the gold and silver yarns will be damaged by chemical substances; therefore, the operation interval of each process should be shortened.

In order to ensure the quality of silk fabrics, it is better to choose composite structure of high temperature resistant gold and silver yarn.

2. When using gold and silver yarns in synthetic fabrics, it is advisable to design more dyeing varieties to avoid high temperature and high pressure dyeing. If some synthetic fabrics need to be dyed at high temperature, it is advisable to select composite high temperature resistant gold and silver yarns.

When heat setting of gold and silver yarn fabrics, it is feasible that the setting temperature is 180 C for less than one minute, because the dry and heat resistance of the yarn is good.

Washing Note: Fabrics containing gold and silver yarn should be washed in time.

Generally, wet and hot washing can be done in warm water below 60 C with neutral soap or soap sheet or soap solution. Dry cleaning can be done with alcohol, gasoline, oil or trichloroethylene, tetrachloroethylene, etc., but the temperature should not exceed 25 C and the time should be controlled within 30 minutes.